Rubber accelerator TBBS synthesis method and the situation in China

2012/5/3 23:34:45Rubber accelerator TBBS synthesis method and the situation in China as follow:

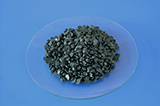

The synthesis method of rubber accelerator TBBS

The synthesis of rubber accelerator TBBS is generally through rubber accelerator M and tert-butylamine existing in antioxidant under condensation, at present the industrial synthesis widespread use of the sodium hypochlorite do oxidant, technology is more perfect. In the aqueous phase adding a bit of surfactants can make M full dispersed, a new method, so as to improve the yield. Japan DongBang rayon company's patent reports yield of 95% ~ 96.7%. Chinese patent describes the one-step direct oxidation of the synthesis of TBBS. In order to avoid sodium hypochlorite oxidation in large Numbers in the formation of the inorganic salts, people developed oxygen or air catalytic oxidation. Aksu, biotechnology and other companies have reported a patent. This method reaction speed, good selectivity and high yield.Akzo company's patent describes the melting point up to 108 ~ 110 ℃, the yield was 99.8%.

The current situation of rubber accelerator TBBS in China

Domestic rubber accelerator TBBS research and development work is from the early 1980s, but for raw materials tert-butylamine synthesis technology problem, the research progress is so slow. Tn recent years, the international statute of limitations on the use of accelerant were introduced, aroused the attention of China's rubber processing and additives industry in China to promote the rubber accelerator NOBS's production is gradually reduced.

The TBBS and its raw material tert-butylamine development is very lively, and made some progress. Shandong Ying Meeting Rubber Additives Co., Ltd.,the successful development of TBBS and its raw materials tert-butylamine has been to market, production capacity of 200 tons per year, it is learned that the company intends to expand production capacity to 2000 tons per year. In addition, the Nanjing Chemical Plant, Shandong aids Factory, organic chemical in a Danxian in Northeast Auxiliary Plant and Tianjin Organic Chemical Plant in the development of TBBS. At present, the development of domestic TBBS involves two aspects, one is the development of raw materials, tert-butylamine, if by urea production method, TBBS cost is too high, users can not accept. The other is the TBBS market has not yet open. At present domestic consumption is the biggest still is rubber accelerator NOBS, and TBBS sales were rare. Although the long term, as domestic to NOBS limit increase,if the the TBBS price control at an appropriate price, its market prospect is very good, but in thenear future its market share is not high.

Hot Product

Rubber Peptizer DBD

Rubber Peptizer DBD Light yellow powder, low poison, no-polluti...

Thiazoles--Rubber Accelerator MBT(M)

Used for NR, IR, SBR, NBR, HR and EPDM. One...

Rubber Peptizer DBD-40

Rubber Peptizer DBD-40 DBD-40 is a chemical peptizer for natural r...

Thiazoles--Rubber Accelerator MBTS(DM)

use as a plasticiser and/or retarder in pol...

Case

Improtant marketing in january

Improtant marketing in january

Sell to Spanish MBT 15tons on 2012.3.6

The company itself has the entitlement to import&export,sells a wide va...

Contact Us

Tel:86-371-63673288

86-371-63659198

86-371-63679318

86-371-86158658

Fax:86-371-63659728

Email: sale@doublevigour.com

Address: 1502, Building 5, Jinyin Modern City, Intersection of Guangdian South Road and Jingsan Road, Jinshui District, Zhengzhou City, Henan Province

Factory: Jijiashan Industrial Park, Heshan District, Hebi City,Hena, China

English

English 中文

中文 русский

русский español

español