Determination of carbon black in rubber products

2013/6/6 20:39:59

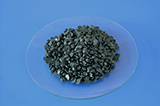

Carbon black is an indispensable raw material of the rubber industry, and the amount thereof after the raw rubber, is one of the most effective and widely used reinforcing agent, the rubber accelerator product important and indispensable component. The carbon black can improve the performance of the vulcanized rubber, to improve the hardness of the rubber material, modulus, and fracture energy, tensile strength, tear resistance, fatigue resistance and abrasion resistance.

Another major role of the carbon black is effective to reduce the cost of rubber products, in particular is used in the silicone rubber, fluorine rubber, and an acrylic ester rubber, and other specialty rubber products. For the latter, the black loading, the better, but excessive carbon black does not contribute to enhanced reinforcement effect, but affect the finish and tensile properties of the products, and increase the difficulty of processing of products, reasonable black loading rubber industry research topic. How accurate determination of the content of carbon black products? This paper introduces a method for determination of carbon black in rubber products.

The basic principle of the determination of the content of carbon black in rubber products is removed through decomposition or degradation of the polymer raw rubber, small organic molecules by solvent extraction, separation by thermal oxidation of inorganic compounds and carbon black. Mainly nitric acid oxidation, the tube furnace high temperature pyrolysis, thermal gravimetric analysis, microwave pyrolysis method and metathesis degradation method. The main difference of the various methods in decomposition or degradation of the polymer in this process. Removal of this two-step basic types of small molecules and the separation of inorganic compounds.

The difference is that the different rubber require different operating conditions, such as the extraction time, the extraction of the solvent used in the choice of solvent, rinsing of residue, and the processing temperature. These two processes see the standard GB 7766-87 and GB 3515-83. The following highlights the different methods of degradation or decomposition of the polymer process.

Hot Product

Rubber Peptizer DBD

Rubber Peptizer DBD Light yellow powder, low poison, no-polluti...

Thiazoles--Rubber Accelerator MBT(M)

Used for NR, IR, SBR, NBR, HR and EPDM. One...

Rubber Peptizer DBD-40

Rubber Peptizer DBD-40 DBD-40 is a chemical peptizer for natural r...

Thiazoles--Rubber Accelerator MBTS(DM)

use as a plasticiser and/or retarder in pol...

Case

Improtant marketing in january

Improtant marketing in january

Sell to Spanish MBT 15tons on 2012.3.6

The company itself has the entitlement to import&export,sells a wide va...

Contact Us

Tel:86-371-63673288

86-371-63659198

86-371-63679318

86-371-86158658

Fax:86-371-63659728

Email: sale@doublevigour.com

Address: 1502, Building 5, Jinyin Modern City, Intersection of Guangdian South Road and Jingsan Road, Jinshui District, Zhengzhou City, Henan Province

Factory: Jijiashan Industrial Park, Heshan District, Hebi City,Hena, China

English

English 中文

中文 русский

русский español

español