The common accelerators in producing rubber

2013/6/4 20:29:53

There are thousands of species of rubber chelating agent used in the production , the role of them in the rubber is also very complex, not only determines the mechanical properties of vulcanized rubber and products performance and life expectancy effect, and also influence the melt processing technology performance and semi-finished products processing quality, the same kind of chelating agent in different raw rubber plays different role of chelating agent with life in the role of gel to different, even the same in the same kind of rubber chelating agent, the role of also more than one. Therefore, we can only according to cooperate with agents in rubber plays the key role of the divided them into sulfurization agent, sulfide accelerator, sulfurization agent, surfactant age-resistant, prevent focal agent, reinforcing the filling agent softening plasticizer, other special chelating agent, etc.

Curing agent: everything that could happen with rubber vulcanization reaction or crosslinking material collectively referred to as sulfurization agent, also known as crosslinking agent.

Curing agent type a lot, and is growing,they have been used the sulfurization agent have sulfur yellow, selenium, tellurium, of sulfur compounds, metal oxide, peroxide, resin, quinonoids class and amine class, etc.

So far since the invention of the rubber vulcanization, sulfur is always natural rubber and most of the diolefins general synthetic rubber main sulfurization agent, it was the emergence of many new sulfurization agent to improve the performance of the rubber products plays a significant all with, but the price is generally more expensive, so still with sulfur yellow primarily. Metal oxide is neoprene special sulfurization agent, in addition to selenium, tellurium outside, other than vulcanization and is mainly used for saturated peptides as sulfurization agent of rubber and special synthetic rubber vulcanization, the most important is peroxide.

Vulcanization accelerator

Curing agent: everything that could happen with rubber vulcanization reaction or crosslinking material collectively referred to as sulfurization agent, also known as crosslinking agent.

Curing agent type a lot, and is growing,they have been used the sulfurization agent have sulfur yellow, selenium, tellurium, of sulfur compounds, metal oxide, peroxide, resin, quinonoids class and amine class, etc.

So far since the invention of the rubber vulcanization, sulfur is always natural rubber and most of the diolefins general synthetic rubber main sulfurization agent, it was the emergence of many new sulfurization agent to improve the performance of the rubber products plays a significant all with, but the price is generally more expensive, so still with sulfur yellow primarily. Metal oxide is neoprene special sulfurization agent, in addition to selenium, tellurium outside, other than vulcanization and is mainly used for saturated peptides as sulfurization agent of rubber and special synthetic rubber vulcanization, the most important is peroxide.

Vulcanization accelerator

If it can speed up the curing reaction speed in compound, shorten curing time, reduce curing temperature, reduce curing agent, and can improve or improve vulcanizates of physical and mechanical properties of the material collectively referred to as sulfide accelerator, hereinafter referred to as the rubber accelerator.

Rubber accelerator can also improve sulfide production efficiency and quality of vulcanized rubber, make thick products vulcanization degree even, and reduce the cost of product.

Rubber industry use many kinds of promoting agents, according to the chemical composition and properties can be divided into two categories, inorganic promoting agents and organic promoting agents. In addition to individual circumstances, common in organic promoting agents. Because the promoting effect, vulcanization features of vulcanized rubber physical and mechanical performance, development is rapid, various kinds.

According to the chemical structure of rubber accelerator which is usually divided into eight categories: thiazole, thiuram, sulfenamide, guanidine, dithiocarbamates, aldehyde amine, xanthogenate and thiocarbamides.

It also can be divided into super speeding grade, speeding, be level, level speeding medium speed level and slow level several types as M for standard. International habits to promote agent M (sh benzene and Margaret) for the standard, all at a faster pace than the M sulfide belongs to or the speeding speeding level, vulcanization rate lower than the belong to medium speed or M slow level, vulcanization velocity is equal to or close to M belonged to the level for speeding. Natural rubber and most synthetic rubber promoting agents are used by the system.

Rubber accelerator and classified according to acid and alkaline, every itself is the acid or hydrogen sulphide reaction after an acidic product for the acidic promoting agents, such as class, thiazole, thiuram,dithiocarbamates and xanthogenate; Itself is an alkaline or and hydrogen sulphide reaction product of the alkali for alkaline promoting agents, such as guanidine aldehyde amine and amine kind; and two conditions for the show neuter neutral promoting agents, sulfonylurea shore-nets was class and thiourea class. This kind of classification in production or more promoter and the situation.

Promoting agents and system, which should have a catch into agent is the main, say give priority to promote agent, also called the first rubber accelerator, and the other one or two kinds of supplementary, called the vice promoting agents, also say to the second, third promoting agents.

active agent

Vulcanization surfactant surfactant, activator, help promote agent. It involved in rubber vulcanization reaction, improve the rubber accelerator activity and give full play to its efficiency, reduce promote agent, and can not only improve the curing speed, and also to improve crosslinking degree, influence crosslinking improve vulcanizates physical and mechanical properties.

Rubber vulcanization surfactant with various species. Divided into inorganic and organic compound two kinds. The most common is zinc oxide and stearic acid and. Dosage for 35 a respectively, and 1.5 2.0 copies. Zno on natural rubber and a certain reinforcing effect. Stearic acid to melt plastic and soften the role, to help spread the mixture of carbon black.

Protection system with the agent

Rubber and its products in the storage and use process, by all kinds of the role of external factors, such as heat, oxygen, ozone, constant metal ions, mechanical force, light, high-energy rays, chemical material and moulds, function, its flexibility, physical and mechanical properties and use performance will be gradually declined, gradually lose flexibility and use value, this phenomenon is called ageing. To prolong the service life of the products, must join some material in the rubber to inhibit or delay the ageing of rubber, these substances collectively referred to as the rubber antiager.

Antiager is various, according to protection principles are classified into physical, chemical and reaction antiager type; According to the protection is divided into antioxidants, antiozonant, curve flexible cracked inhibitors, harmful metal inhibitors, ultraviolet ray absorber, etc.

Hot Product

Rubber Peptizer DBD

Rubber Peptizer DBD Light yellow powder, low poison, no-polluti...

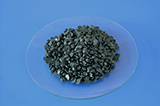

Thiazoles--Rubber Accelerator MBT(M)

Used for NR, IR, SBR, NBR, HR and EPDM. One...

Rubber Peptizer DBD-40

Rubber Peptizer DBD-40 DBD-40 is a chemical peptizer for natural r...

Thiazoles--Rubber Accelerator MBTS(DM)

use as a plasticiser and/or retarder in pol...

Case

Improtant marketing in january

Improtant marketing in january

Sell to Spanish MBT 15tons on 2012.3.6

The company itself has the entitlement to import&export,sells a wide va...

Contact Us

Tel:86-371-63673288

86-371-63659198

86-371-63679318

86-371-86158658

Fax:86-371-63659728

Email: sale@doublevigour.com

Address: 1502, Building 5, Jinyin Modern City, Intersection of Guangdian South Road and Jingsan Road, Jinshui District, Zhengzhou City, Henan Province

Factory: Jijiashan Industrial Park, Heshan District, Hebi City,Hena, China

English

English 中文

中文 русский

русский español

español