The relationship between time and temperature of the vulcanization and accelerator

2013/6/4 20:48:46

Industrial products production often seek is the lowest temperature, the shortest time sulfide. When think vulcanization time is too long, often is to increase the accelerator, or improve the curing temperature, but the actual such procedure is wrong.

1. Because the temperature in the rubber vulcanization decision varieties, such as the best natural rubber vulcanization temperature for 145-148 degrees, butyl benzene, butyl rubber, butadiene rubber so the best curing temperature for 148-153 degrees, silicone rubber vulcanization temperature for 170-175 degrees. In the practical operation do temperature adjustment in the temperature of filter based general add 3-5 degrees or so. Curing temperature setting is should not change. If change will affect the physical rubber. At the same time in the process of production will appear such problems.

1. Because the temperature in the rubber vulcanization decision varieties, such as the best natural rubber vulcanization temperature for 145-148 degrees, butyl benzene, butyl rubber, butadiene rubber so the best curing temperature for 148-153 degrees, silicone rubber vulcanization temperature for 170-175 degrees. In the practical operation do temperature adjustment in the temperature of filter based general add 3-5 degrees or so. Curing temperature setting is should not change. If change will affect the physical rubber. At the same time in the process of production will appear such problems.

2. The time is set to sulfide ju products of the thickness and operation requirements to set. Because the thermal conductivity of the rubber is bad. The thicker products the longer sulfide. The setting of the time acquired sulfide filter different products and set different curing time. Thin products fluidization time is too long to productivity and a waste of energy. Time is too short thick products sulfide, outside the coke not familiar the serious influence quality.

3. In order to improve the speed of sulfide generally there are two ways first is heating, again a is to increase promote agent or convert super ultra accelerators, such as heating to property of the product is not high demand can take an examination of the filter. But it is difficult to control. According to the theoretical calculation because every improve 10 degrees vulcanization time about shorten time less than half. Such as improving temperature should also calculate how much should be improved by such temperature. Increase or decrease in promoting agents to adjust the fluidization velocity is a common method, it must be in the set temperature and time, and then increase or decrease to adjust the accelerator.

To adjust the accelerator is to have cultured, for promoting agents and sulfur in the solubility of rubber is very small. When more than its solubility it run out, appear spray frost phenomenon. And property also want to have a big change.

Practice has proved, ordinary products to promote agent should be as little as possible. Add promoting agents should not according to the proportion. Should increase or decrease in the second and third promoting agents, improve the activation performance. So can effectively control the accelerator spray frost, so as to not affect the product's property and stability.

Improve productivity can't completely from reduce curing time to take an examination of filter. General factory is from operators increase operation mould to test the number of filter. Blind increase promoting agents, increase the temperature, to increase production have the following harm: 1. Property effect. 2. A spray of frost may. 3. To melt the sulfur. 4. Compound big viscosity, performance is poor, not easy operation sulfide.

At present home has a lot of rubber factory production 8 MM thickness process of the moulded products, the DM-M- -TMTD-D accelerator four and collocation is a kind of very good formula, he is the advantage of sulfide curve flat, coke burning time long, easy control, not easy spray frost.

DM for the first accelerator decided to in the whole process of sulfide, and in four kinds of promoting agents in most dosage, and decided to some kind of property in rubber. In general should not increase or decrease.

M as the amount of less it can improve vulcanization rate, as a second promoting agents use. In the process of sulfide it and DM is both to each other and activation of inhibition each other, this to the speed control and sulfide plays a key role. And is a kind of plastic solution agent, be helpful for rubber molecules plastic solution.

TMTD is the third accelerator it is a super ultra promoting agents used in accelerating curing speed, general dosage not more than 10% of the DM, or with more easily melt from sulfur, plastic materials that sex decline. Promoting agents D itself is a medium speed promoting agents. When a single sulfide at a modest pace, general for thick products. But it is a kind of alkaline promoting agents, and DM and M and can be quickly when activated, vulcanization rate speed up immediately. It as help promote with agent, mainly used as activator, used to hold accused of curing speed. In general not more than 20% of the DM. It in the control speed adjustment with TMTD sulfur together for good. TMTD under high temperature will resolve the M rapidly active D/DM.

Different solubility promoter in rubber is different, the variety of promoting agents and can reduce a single promote after the dosage. To control the rubber products of promoting agents spray plays a key role frost. Also greatly to place the adjustment of the rate of sulfide show. Different property, different coke burning, different curing time, application of different accelerator is tie-in. Blind to improve the temperature to accelerate the speed of sulfide sulfide is one of the most stupid practices.

Using the best temperature vulcanization, reasonable use to promote agent collocation, so could design the curing speed, property good formula, in daily production is, want to pursue a fast in 1.5 points below sulfide can use M/H or M/TS and for general coke burning, faster speed of sulfur in three points to promote the following can use DM/D/TMTD, 4.5 minutes can be used in the DM/M/TMTD and. Similar and are legion.

The best time is not easy also sulfide and decide, based on the thickness of the products, vulcanization temperature calculated, computational formula books I also not much about some, usable also practice experience office estimates, 6 MM according to the following T90 time, more than 6 MM can press T90 + (m-6) minutes calculation. Can produce a kind of excellent products in addition to have a reasonable good formula.

Hot Product

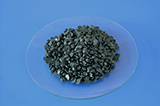

Rubber Peptizer DBD

Rubber Peptizer DBD Light yellow powder, low poison, no-polluti...

Thiazoles--Rubber Accelerator MBT(M)

Used for NR, IR, SBR, NBR, HR and EPDM. One...

Rubber Peptizer DBD-40

Rubber Peptizer DBD-40 DBD-40 is a chemical peptizer for natural r...

Thiazoles--Rubber Accelerator MBTS(DM)

use as a plasticiser and/or retarder in pol...

Case

Improtant marketing in january

Improtant marketing in january

Sell to Spanish MBT 15tons on 2012.3.6

The company itself has the entitlement to import&export,sells a wide va...

Contact Us

Tel:86-371-63673288

86-371-63659198

86-371-63679318

86-371-86158658

Fax:86-371-63659728

Email: sale@doublevigour.com

Address: 1502, Building 5, Jinyin Modern City, Intersection of Guangdian South Road and Jingsan Road, Jinshui District, Zhengzhou City, Henan Province

Factory: Jijiashan Industrial Park, Heshan District, Hebi City,Hena, China

English

English 中文

中文 русский

русский español

español