Design of the vulcanization system and the application of sulfide accelerator

2013/6/4 23:25:56

The rubber vulcanization system including the sulfurization agent, promoting agents and active agent, generally speaking the rubber crosslinking related to how much of the main agent of vulcanized rubber , of course,the increasing of the groups containing promote agent can also with single or double sulfur key in the form of sulfur key to improve parallel density, general sulfur yellow vulcanization system in promoting agent less, so the size of the crosslinking density is mainly dependent on the amount of sulfur yellow.

The role of the promote agent is to reduce sulfur yellow crosslinking temperature, speed up the sulfur yellow curing speed, actual it is the role of a catalyst, different types of promoting agents activation energy is different, so the rubber type sulfide is endless also and same, such as, EPDM, IIR for unsaturated double bond of the less so slow speed of sulfide, general use of highly reactive two amino acid salt content and promote the agent or autumn lamb kind of give priority to promoting agents, and unsaturated double bond of the much NR, IR, BR, SBR, NBR for curing speed, use commonly Margaret class or time of sulfonylurea amide promoting agents give priority to promote agent. The choice of promoting agents are usually contains some of the groups acid sulfide accelerator, can also participate in sulfide groups of sulfide reaction, helps to reduce the vulcanizates of sulfide in after the nets material, in order to reduce the spray frost phenomenon.

The Lord promoting agents can use one or two above, generally promote agent the stronger the higher activity activation energy, acid, the better use in more than two main promoting agents must idea when their synchronization activation, active strong Lord promote agent less active somewhat weaker Lord promote agent more, in order to reach the acidic balance and synchronization of the active effect.

High saturated in the rubber Lord sulfide accelerator is usually used, but sometimes in order to make a variety of rubber and achieve the best of sulfide characteristics or need to design of the longer the vulcanization system through period when there are two kinds of main promoter.

In the low unsaturated rubber EPDM, IR in general use two or more to promote the Lord agent, because the two rubber vulcanization speed slow, promoting agents in the solubility rubber low, such as single promote agent will greatly increase, a reaction to the promotion of the not agent and reaction of the material after expels net surface formed spray frost. In a variety of Lord promoting agents and also must idea when their synchronization activation, or you will make the activation of a by another accelerator reaction after not buy in rubber, when the temperature drop vulcanized rubber or outside the environmental impact still can appear spray frost phenomenon.

Deputy promoting agents also called the second accelerator general is mainly used to adjust coke burning time or activation energy use, low in saturated rubber is mainly used to adjust the time and the use of coke burning, and high in saturated rubber, not only for regulating the coke burning time, but also to speed up common activation vulcanization rate, also helps to reduce the spray frost phenomenon. General in the high unsaturated rubber vulcanization system design in the recipe when when vice promoting agents use.

In the design of sulfide system sometimes use the accelerator, in fact, is a kind of activator, low in saturated in rubber adhesive generally use minus sex promote agent (such as promoting agents D), high in saturated rubber gel to also use alkaline promoting agents, sometimes use strong activity of autumn lamb class promoting agents, general dosage is very few, in the main promoter of about 10%, its purpose is to fully activate the accelerator, shorten the thermal curing time, and in effect of too much less than the focal burn time, help to promote the agent Lord fully reaction, reduce the accelerator in the rubber withhold. So sometimes also can reduce the rubber injection frost phenomenon.

Zinc oxide, stearic acid and surfactant rubber vulcanization system is an important component part, zinc oxide, stearic acid, promoting agents, sulfur yellow reacts with the pioneer of sulfide reaction and zinc complex (mercaptan salt), formed a activation vulcanization system, whether the content of zinc oxide insufficient or stearic acid purity is not high will affect the curing reaction of the synthesis of salt pioneer mercaptan, make rubber the crosslinking density of the lower and not the reaction in the rubber accelerator for increasing the lien, and rubber will appear spray frost phenomenon. The facts in the solubility promoter rubber in low temperature sulfur rubber in always not more than the solubility of rubber, though the solubility promoter in rubber is not high, but the reaction of synthesis in the rubber mercaptan salt has high solubility. So we are generally in the rubber vulcanization process, owe sulfur can cause spray frost also it is for this reason.

In the rubber formulation sometimes promoting agents to join so many also won't appear spray frost, sometimes promoting agents to join rarely also can appear when spray frost, this is rubber processing units often appear problem, this and the collocation of sulfide system rationality is not divided, a by sulfur yellow, promoting agents, zinc oxide, stearic acid matchs and become the response of the system of sulfide balance is very important, too much sulfur yellow too little to promote cooperation system will make agent sulfur yellow remaining, and appear spray sulfur phenomenon. Too many accelerator too little sulfur yellow also can make the system of the accelerator reaction not over, a part of experience in sulfur decomposition active sulphur, using in the amount of sulfur in a body vulcanization, sulfur yellow dosage should be moderate decrease, so high temperature and high promote rapid vulcanization system collocation balanced, whether sulfur yellow or promote the dosage of the agent much more than the solubility of rubber, and make product so won't spray frost. A variety of promoting agents collocation point don't balance will make the activation of a kind of promoting agents reaction is not complete, withhold produced more spray.

In the design of sulfide system must be from the entire system process performance all aspects to consider, especially in the design EPDM, IIR sulfur yellow vulcanization system, not only should consider first used in the rubber dissolve of solution promoter variety, and also want to consider the sulfur yellow and promote the use of different proportion, agent to promote the active agent and proportion, the dosage and oxidizing activators of dispersion, and other factors. Should decrease as far as possible vulcanizates after in the reaction to promote agent in the form of the withhold rubber.

To speed up the vulcanization reaction speed is not to rely on to adjust the temperature increase but by promoting agents the different breed reasonable collocation to speed up. Some high unsaturated rubber vulcanization speed can be from dozens of seconds to a few hours to arbitrarily regulate, and so won't appear any such as spray frost. Promoting agents variety selection and not fixed to choose, as long as meet the technological property requirements, sometimes can match a variety of combination can be full of requirements, so a lot of choice sometimes receives the craft habit.

When the choice of sulfide promote agent will sometimes according to technology, equipment, mould factors and decide, because the environment, temperature, curing time can cause instability of sulfur, owe products such as sulfur many unfavorable factors, this time should be chosen vulcanization flat better sex sulfide accelerator give priority to promote agent. Sometimes need to consider the transparency or discoloration and so on, should choose high temperature is not easy to change color of the accelerator.

In selecting promoting agents and choose vulcanization time, not only should consider promoting agent varieties to rubber physical properties of the influence and even the proper control of curing speed, because of the fast reaction rate will increase vulcanized rubber internal nets collaterals chain rupture, and the aging properties of products are extremely adverse.

In selecting promoting agents and choose vulcanization time, not only should consider promoting agent varieties to rubber physical properties of the influence and even the proper control of curing speed, because of the fast reaction rate will increase vulcanized rubber internal nets collaterals chain rupture, and the aging properties of products are extremely adverse.

Some fall in use of inorganic packing, because its are acidic or surface hydroxyl group adsorption rubber molecules, make the sulfur rubber slowed, then in the design formula should not be increased by way of promoting agents to speed up the curing speed, and should add some alkaline of the modified surface agent, such as PEG, DEG and active agent, to improve vulcanization speed.

In the use of white carbon black plastic materials, such as DEG, PEG surfactant is also such, time was Margaret sulfonylurea promoter of active, the mature craft sometimes also can use them to adjust the system of sulfide. Reducing the amount of low promoting agents.

In the design formula should be taken into consideration when all kinds of chelating agent for rubber vulcanization speed, the effect of the general acid chelating agent easy decomposition strong activity of promoting agents, at the same time also inhibit activation energy of promoting agents. Make rubber vulcanization slowed, in the design or debugging vulcanization system should take note. Zinc oxide, stearic acid also surfactant and usage of reinforcing agent and structure, and specific surface area, relevant, opposite for the higher the structure, the greater the table of zinc oxide than the more difficult the scattered, stearic acid increase dosage should be moderate, open when mixing mill mixed refine than close relative of dispersion poor mixing mill, also should be appropriately increase of stearic acide.

In the design of sulfide system must also be from the whole formula and physical property Angle to consider, and promote the active agent with mutual relationship between activation is very important, especially for the above two main promoter and must do more comprehensive sulfur when creep test. To ensure the rubber vulcanization system activation energy.

Hot Product

Rubber Peptizer DBD

Rubber Peptizer DBD Light yellow powder, low poison, no-polluti...

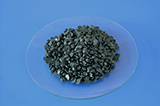

Thiazoles--Rubber Accelerator MBT(M)

Used for NR, IR, SBR, NBR, HR and EPDM. One...

Rubber Peptizer DBD-40

Rubber Peptizer DBD-40 DBD-40 is a chemical peptizer for natural r...

Thiazoles--Rubber Accelerator MBTS(DM)

use as a plasticiser and/or retarder in pol...

Case

Improtant marketing in january

Improtant marketing in january

Sell to Spanish MBT 15tons on 2012.3.6

The company itself has the entitlement to import&export,sells a wide va...

Contact Us

Tel:86-371-63673288

86-371-63659198

86-371-63679318

86-371-86158658

Fax:86-371-63659728

Email: sale@doublevigour.com

Address: 1502, Building 5, Jinyin Modern City, Intersection of Guangdian South Road and Jingsan Road, Jinshui District, Zhengzhou City, Henan Province

Factory: Jijiashan Industrial Park, Heshan District, Hebi City,Hena, China

English

English 中文

中文 русский

русский español

español